Innovative packing for brake boosters

Enabling better transport capacity utilisation and enhanced ergonomics for workers producing brake boosters for Volvo Cars.

The challenge

The purpose of the solution is to protect the delicate MKC1 brake boosters manufactured by Continental during transport to Volvo Cars facilities around the world. The solution is built according to daily demand and then transported from the aPak 3PL mounting factory in Frankfurt to Continental, where it is filled with brake booster units. From there it ships by truck or boat to production facilities in Europe as well as China, the USA and Malaysia. Thanks to well-coordinated just-in-time deliveries, customers do not need to hold large inventories of products. For extra security, reserve stock is always available in Frankfurt, located just minutes away from Continental.

The brake booster in this case is a brand-new unit that imposed new requirements on the packaging because its weight exceeds 5 kilograms. Whereas the previous unit could be handled manually, the heavier unit has to be handled by machine. To meet the new requirements, the design needed to be tailored to accommodate two different robot tools, and it also had to meet the strict demands and regulations applicable in the various production facilities around the globe. The design had to be adapted with precision because it was going straight into the production line, both via sequence packing and lineside, so that the robot tool could precision lift the unit directly into the car.

The solution

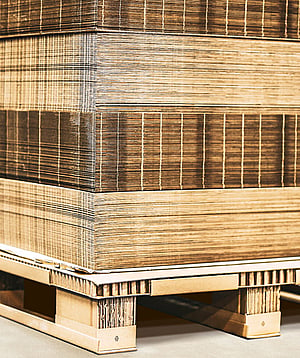

APak AB and Mondi Ansbach developed the innovative packaging solution BrakeBox in close cooperation with Continental AG. The new construction dispenses with crossbars for the compartment. This innovative change means that 18 units can now be packed instead of the previous 12 units. This is a major benefit for the customer in terms of logistics, but also an important contribution to the environment. With almost the same material input, the packing density was increased by 50%. In relation to the total number of parts, the raw material, freight and storage volume saving is approx. 33%. Regardless of the means of transport, the footprint of the packaging always ensures full utilisation of the cargo space, so that the maximum number of units are shipped every time.

100% corrugated

The packaging is made entirely of corrugated cardboard – produced from renewable raw materials and fully recyclable. Some industrial logistics chains continue to use packaging systems and materials that do not reflect Mondi’s principles as regards construction or ecology. We work closely with our customers according to Mondi’s 3R rule (Reduce, Replace, Recycle) for sustainable packaging.

More on industrial packaging

Discover our easy to use, lightweight and recyclable packaging for large or heavy products. See industrial packaging in a whole new light.