Closing the loop: Turning packaging waste into value with circular solutions

This article explores what it takes to go from circularity goals to practical, data-driven results. From smart design to system-wide thinking, this approach has helped leading brands turn goals into results.

When Biedronka set out to reduce the environmental impact of their packaging, they quickly realised the issue wasn’t just materials—it was systems. They needed packaging that protected products, fit their logistics model, worked with recycling infrastructure, and could scale across thousands of stores.

At Mondi, this is a challenge we see more often. Circularity has become a guiding ambition for many businesses, but turning that concept into reality—without compromising performance or cost—is where things get complex.

Define what circularity really means for your business

There’s no one-size-fits-all definition. According to the Ellen MacArthur Foundation, a circular economy is about keeping materials in use through processes like maintenance, reuse, recycling and composting. But in packaging, the practical interpretation can differ by product, industry, or market.

For paper-based packaging, one important nuance is that fresh and recycled fibres are complementary elements, helping to maintain the paper cycle without compromising product quality or strength. This means that even the most circular solution will require some input of fresh fibre.

That’s why the first step is to zoom out and understand how sustainability, functionality, and supply chain goals connect—and where trade-offs might appear.

Reducing waste was only part of the challenge—we also had to rethink how the packaging flowed through our supply chain.

Sustainability Director at Biedronka, Poland’s largest retail chain

Design for impact from day one

Studies show that up to 80% of a product’s environmental impact is determined at the design stage . That’s why we focus on circularity from the very beginning—selecting the right paper grade, optimising structure, and reducing materials where possible.

It’s not just about making packaging recyclable. It’s about designing it to stay in circulation longer, perform better with fewer resources, and lower emissions across its lifecycle.

For protective packaging, solutions like flat-packed corrugated alternatives can replace conventional materials such as expanded polystyrene (EPS) packaging, offering both performance and recyclability. These are particularly relevant for sectors like electronics or home appliances, where product protection and brand perception are closely linked.

Let data guide your decisions

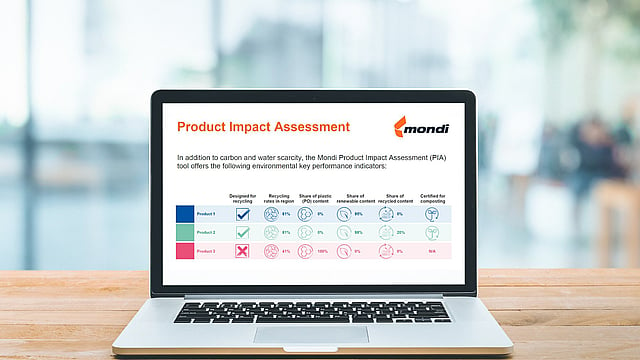

Knowing which solution is most circular isn’t always obvious. That’s where our Product Impact Assessment (PIA) tool comes in. It helps compare packaging options using lifecycle data across key indicators like carbon footprint and water use. PIA provides real decision support—giving customers clarity on the trade-offs behind material choices, recyclability, and design tweaks.

Customers want to achieve ambitious sustainability goals while ensuring that packaging performance and product protection remain intact. With PIA, we can show what happens when you change parameters, materials, weights or designs—before anything is produced.

Remy Eecke, Sustainability Manager, Mondi Corrugated Packaging

Understanding the environmental impact of products and packaging solutions is key.

Build solutions that perform in the real world

Circularity doesn’t stop at theory. Performance matters—especially for industries with high product protection needs or complex supply chains.

Testing also plays a role in validating circularity. Packaging needs to perform—not just in transport and storage, but also in recycling streams. Suppliers often offer in-house testing based on industry standards such as the Cepi test method or 4evergreen protocols, helping ensure fibre-based solutions meet both technical and environmental requirements. This ensures that circular packaging doesn’t just sound good on paper—it works in practice.

Collaborate across the value chain

No company can achieve circularity alone. That’s why we work closely with customers, suppliers and industry partners to align efforts—from pilot projects to tried and tested closed-loop systems.

The Biedronka partnership shows how this can work: together, we designed a solution that uses recycled materials, keeps fibre in use longer, and integrates into their logistics model.

Working with Mondi helped us go beyond targets and implement real change—reducing waste and building a more circular packaging system.”

Sustainability Director, Biedronka

.png?stamp=b207be2d930009ad2467da1101a02d575776f719)

Turning packaging challenges into circular solutions

Circularity in action—every step counts

There’s no shortcut to circularity. It takes data, design, innovation and collaboration. But the rewards are worth it: reduced environmental impact, smarter use of materials, and solutions that meet both business and customer expectations.

What’s the next step in your packaging journey?

We’re ready to take it with you.

.jpg?stamp=da00078c4e45e9c75c4880da93e344778b487a04)