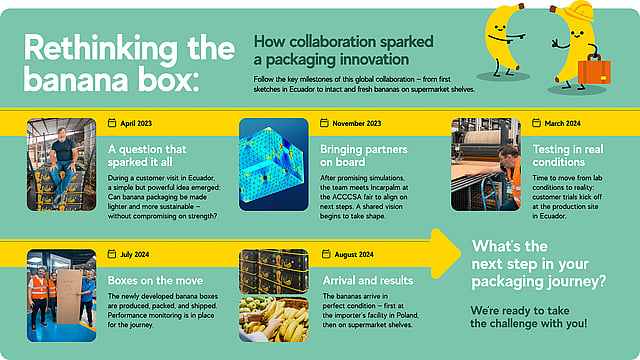

Rethinking the banana box: How collaboration sparked a packaging innovation

From breakfast smoothies to fruit bowls, bananas are a favourite across the globe. But getting them onto store shelves in top condition takes more than just careful handling—it requires packaging that’s strong, consistent, and sustainable.

So when Mondi’s team of containerboard technical experts began exploring a thought-provoking question during a customer visit in Latin America, it set off a journey of innovation, sparked by curiosity and fuelled by collaboration: “Could the standard banana box be made lighter and more sustainable—without compromising on strength?” It wasn’t just a product brief. It was an opportunity to rethink a packaging standard that had stood the test of time.

Challenging convention

The banana box is a fixture of global fruit logistics: sturdy, proven, reliable. For many, it’s not something to be questioned. But for Marek, one of Mondi’s technical experts for containerboard solutions, the question from that business trip stuck with him.

On the flight back to Europe, he began testing it in theory. Could a different paper mix reduce weight? Would it withstand a month-long journey across the Atlantic in a high-humidity environment? Could performance be maintained while increasing sustainability parameters regarding the material composition? These weren’t small questions. But they were worth exploring.

Building a new box composition, together

Back in Poland, Marek brought the idea to the technical sales team. Together, they began testing and simulating different scenarios—analysing how paper combinations behaved under pressure, moisture, and time.

From the outset, the project was collaborative, involving trading partner Europcell, the major Ecuadorian banana exporter Incarpalm, and a leading European importer. Over weeks of coordination, testing, and shared expertise, a multinational partnership began to take shape.

What made this collaboration different wasn’t just the technical ambition—it was the open dialogue. Customer, converter, paper expert, and supply chain partner working as one team, across continents and time zones. “We didn’t start with a finished solution—we built it step by step,” says Marek. “Every partner added a piece to the puzzle.”

A box that’s lighter, stronger and smarter

The teams developed a new banana box concept: one that combined ProVantage SmartKraft Brown, known for its superior strength and optimal protection, with ProVantage Frescoflute, a semi-chemical fluting designed to enhance the firmness of lightweight packaging boxes.

The result? A box that’s just as strong—but made with approximately 40% recycled fibre, and up to 10% lighter than the previous design. Less weight means lower emissions during shipping, without risking damage to the fruit inside.

Putting it to the test under real conditions

Designing a promising prototype is one thing. Proving it is another. In summer 2024, Marek flew to Ecuador again—this time to supervise a full-scale production trial. Bananas were packed into the new boxes and loaded into two shipping containers bound for Europe. Sensors placed inside tracked parameters such as humidity and temperature throughout the 33-day journey.

“We saw humidity levels between 96 and 100%—extreme conditions for any packaging,” Marek says. “But the boxes held up. No collapse. No compromise.” For him, seeing the final result wasn’t just a technical win—it was personal. “It was one of the most meaningful moments in my career. To see something that started as a question turn into a working solution—that's why we do this.”

The reliability of the box is everything. Seeing the new box composition perform under the toughest conditions proves that innovation and practicality can go hand in hand.

Jorge Romero, Operations Manager at Incarpalm

Looking ahead: A ripple effect

The successful trial has opened up new conversations with other fruit exporters and retailers across various regions. As new regulations come into force—including a 2026 ban on plastic wrap inside banana boxes—the need for innovative, fibre-based packaging solutions will further grow.

“This collaboration is a great example of how to approach an end-use application from a different angle,” says Gijs Huisman, Sales Director at Mondi Containerboard. “It’s about listening, co-creating, and delivering something that works for the entire value chain.”

Shaping the future of fruit packaging

What began with one customer’s question became a global collaboration—and a working solution that delivers on strength, sustainability, and performance. The new banana box composition is more than just a packaging innovation. It’s a story of partnership, shared ambition, and what's possible when we rethink the familiar.