Release liner for graphic arts

Mondi's innovative release liner for car wrapping, advertising films, in-store advertising, public and exhibition displays and banners, signs and reflective films.

- Excellent lay-flat characteristics

- Adjustable degrees of rigidity

- Structured liner available for utmost results

Benefits

- Optional digital liner with a lacquer to absorb volatile molecules of uncured silicone and avoid transfer onto print surface

- Optional sealed edges for protection against ambient moisture absorption

- Large range of in-house test methods

- Release values can be adjusted according to our customers’ requirements

- Unprinted or printed on the reverse side or under silicone

- Individual packing and slitting possibilities on customer’s demand

Sustainability

- NextLiner: The world’s first more sustainable PCK liner, based on 100% recycled fibres. Renewable polymer coating available.

- AirXLiner™ CCK: Plastic free, more sustainable kraft paper, solvent-free silcone, available up to 135gsm

Applications

- Car Wrapping

- Advertising films (vinyl, PET, PVC, etc)

- Vehicle marketing

- Traffic and safety (signs and reflective films)

- In-store advertising, public displays and banners

Downloads

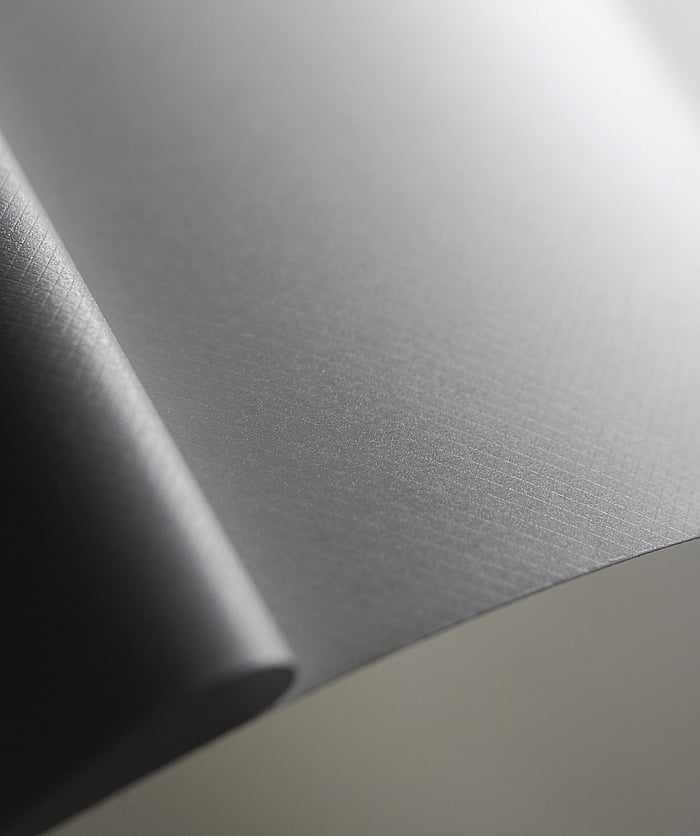

Smooth operator

Mondi's innovative AirXLiner™ offers an easy release, paint-like finish to wrap your next masterpiece in.

By focusing on the three pillars of air egress, the ability to slide and reposition the wrap, and the invisibility of its performance features, we can offer the perfect, bubble-free surface you need.

No more bubbles

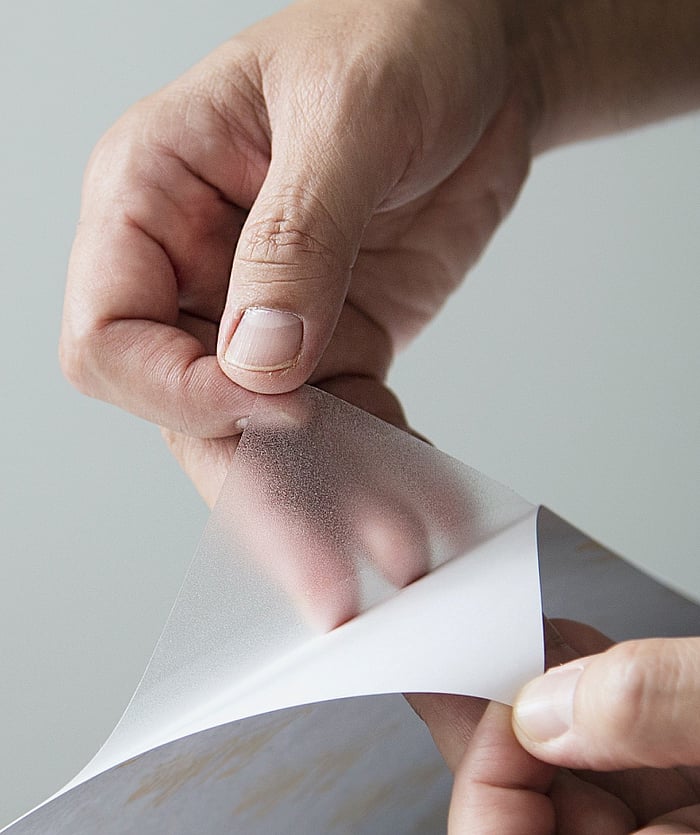

Mondi's AirXLiner™ presses a system of microscopic canals onto the adhesive layer of the film during the production process, creating canals to release trapped air. If bubbles form when the film is applied to your surface, you can easily push them out. No air release tool required.

Wriggle room

Air canals aren't the only thing you'll find when AirXLiner™ is under the microscope. We have added thousands of tiny peaks that keep most of the adhesive from touching your surface, allowing the wrap to slide easily until firm pressure if applied. And even then, AirXLiner's matte adhesive enables the wrap to be removed and repositioned, until it sets 24 hours later.

Flawless finish

Our advanced technology not only provides the air canals, peak and matte adhesive to provide a smooth, sliding and repositionable finish, it makes these features invisible. By absorbing the shallow channels into its adhesive layer after application, AirXLiner achieves a paint-like finish

Featured news

Similar products

Release liner for fibre composites

Release liners are essential for producing composite materials. They serve as process paper or film to prevent materials from sticking together during the impregnation process.

Medical release liner

Release liners for medical applications including transdermal delivery systems, therapeutic patches, adhesive bandages, advanced wound dressings, and body electrodes.

Release liner for labels

Using all kinds of base materials, and adjusting chemistry to customise release values, we offer tailor-made solutions that are sustainable by design.

Release liner for hygiene applications

Sustainable and cost-effective paper-based release liners designed for customers’ specific adhesives, contribute to efficient self-adhesive hygiene solutions.

.jpeg?stamp=7f1787ba642a6412274f32665ec5257646022099)